Hazards handled

Target the daily risks slowing output and raising incident rates.

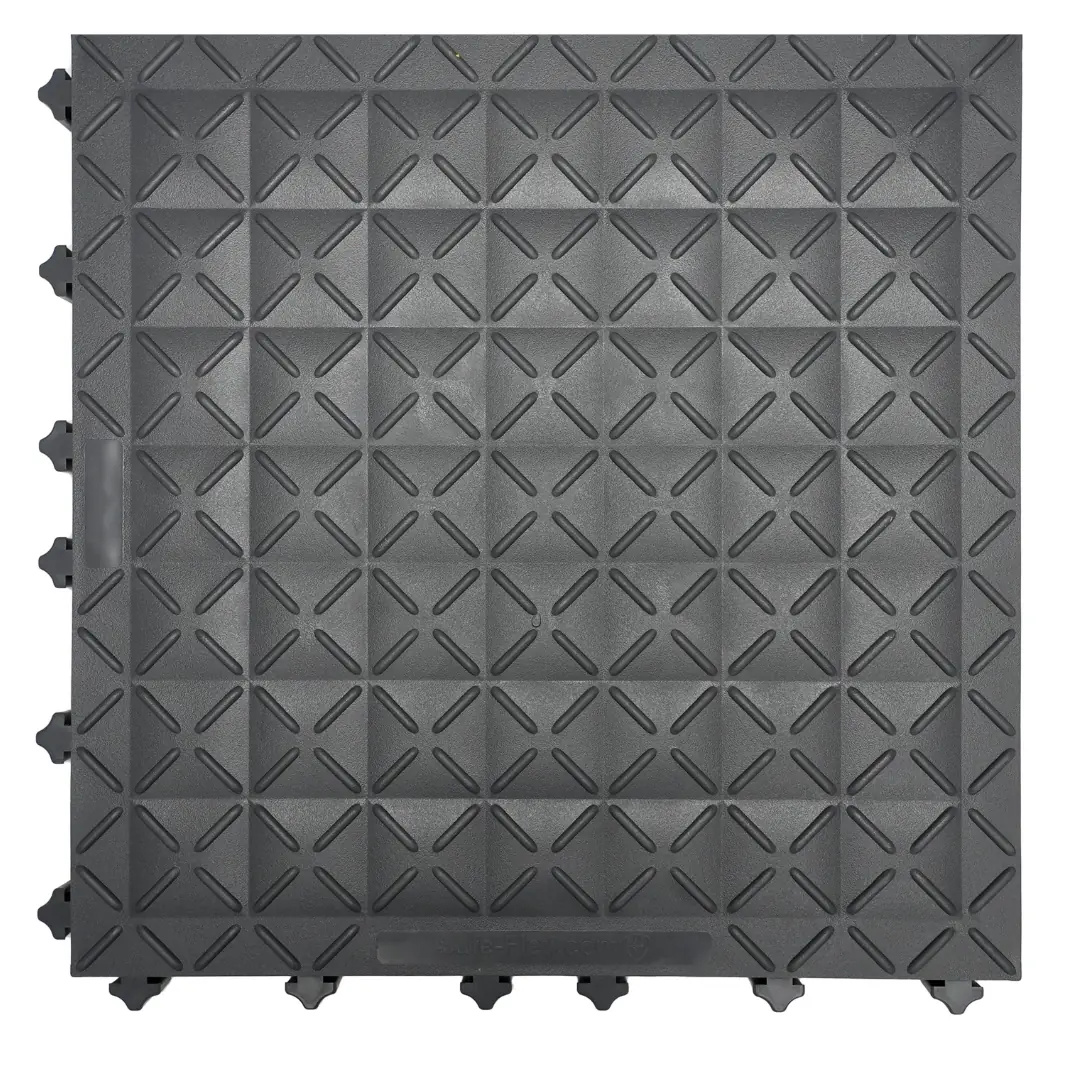

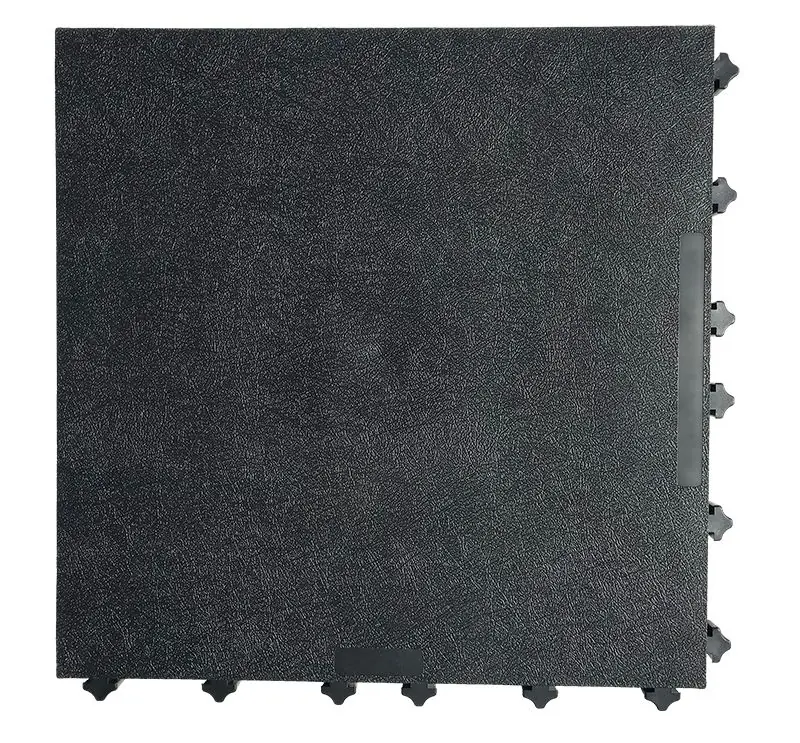

- Coolant, cutting oils, and swarf collecting underfoot during production shifts.

- Hot-work sparks and grinding that degrade traditional PVC matting.

- Fatigue and MSD risks from operators standing through 10+ hour runs.