SAFE-FLEX INSIGHTS

The matting refresh checklist to run during maintenance week

Use this 45-minute walk-through to capture data, prioritise high-risk zones, and brief installers before shutdown begins.

- maintenance

- planning

- shutdown readiness

Why plan matting alongside mechanical inspections?

Facilities teams already block time for guarding checks, LOLER inspections, and calibrations. Adding a structured matting sweep to that cadence delivers outsized value because technicians are already at the workstation with PPE, access, and authority to lock-off areas. Skipping it typically means emergency orders later in the quarter.

The 45-minute on-foot workflow

1. Map priority zones (10 minutes). Print or load the existing CAD/Planner layout and highlight areas with standing time greater than 30 minutes per cycle, fluid exposure, or forklift interaction.

2. Capture wear data (15 minutes). For each zone, log:

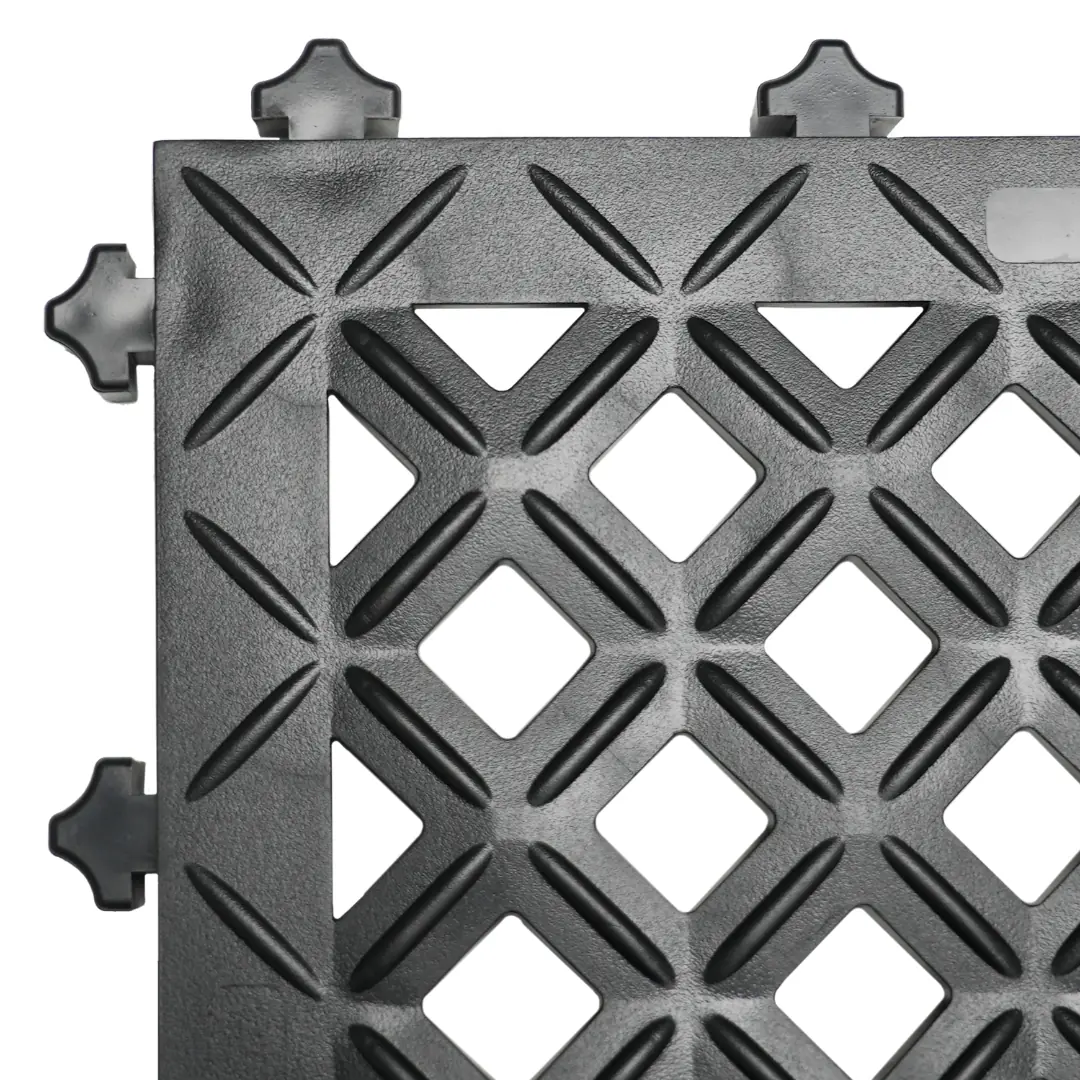

- Visible cracking, curling, or compression set.

- Drainage flow (slow, blocked, or free).

- Edge security (any lifted bevels or loose connectors).

- Cleaning compatibility (chemicals used vs. compound spec).

3. Flag compliance documentation (5 minutes). Check that the location’s RAMS pack, slip certificate, and warranty data are accessible. If not, note the doc gap so we can reissue digital copies.

4. Photograph and annotate (10 minutes). Use a phone or tablet to capture wide shots plus detail images. Annotate directly in the Safe-Flex planner so quantities and edging notes are locked in before ordering.

Turning notes into an execution pack

Drop the captured data into the planner or email it to our project desk. We respond with:

- Updated CAD layout reviewed by our West Midlands design team.

- Line-item BoM with pricing and lead times.

- Installer brief (DIY or our crew) plus risk assessments.

Bonus: build a recurring calendar entry

Make the audit repeat automatically: one week before maintenance week, the checklist email arrives with the previous report attached. Teams stop reinventing the wheel, and the board sees a clean compliance trail for every shutdown. It is the simplest way to keep matting as predictable as the rest of your TPM programme.

Ready to upgrade your facility?

Get expert advice on your matting requirements

Our team can help you specify the right matting for your application—whether it's ESD protection, anti-fatigue, or slip resistance. All products UK-manufactured from recycled materials.